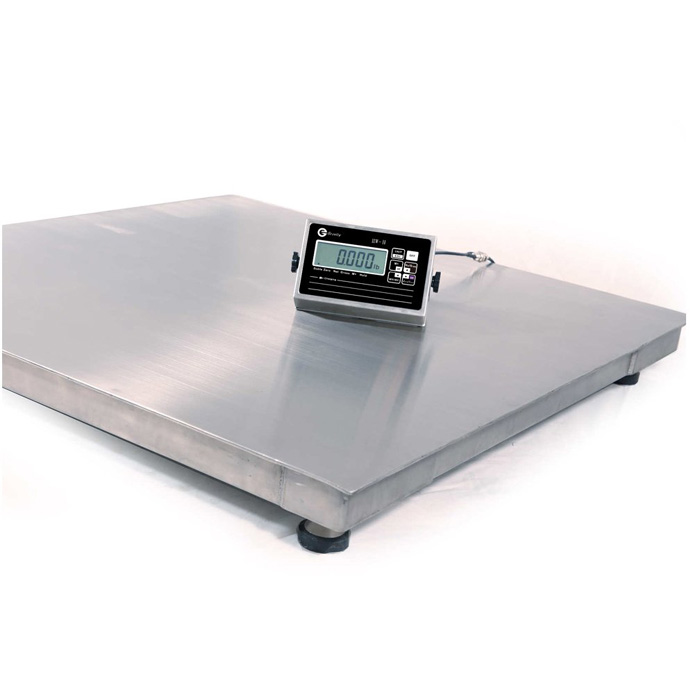

In Kenya’s fast-growing food processing industry, businesses face constant pressure to maintain high levels of accuracy, hygiene, and efficiency. From meat and fish processing plants to flour mills, bakeries, and beverage manufacturers, weighing solutions play a critical role in daily operations. One tool that stands out is the stainless-steel floor scale—a durable, hygienic, and reliable choice that supports both compliance and productivity.

This article explores the major benefits of stainless-steel floor scales and why they are the ideal option for food processing facilities in Kenya.

1. Hygiene and Food Safety Compliance

One of the greatest advantages of stainless-steel floor scales is their exceptional hygiene properties. In food processing environments, spills, oils, and moisture are unavoidable. Traditional mild-steel scales may rust, corrode, or trap bacteria in crevices, leading to contamination risks.

Stainless steel, however, is:

-

Non-porous – making it resistant to bacteria build-up.

-

Easy to clean – smooth surfaces allow quick washing and sanitization.

-

Corrosion-resistant – even when exposed to water, chemicals, and cleaning agents.

For Kenyan food processors seeking to comply with KEBS (Kenya Bureau of Standards) and international food safety standards (HACCP, ISO 22000, etc.), stainless-steel floor scales ensure a higher level of hygiene and reduce the risk of costly recalls.

2. Durability and Long-Term Value

Food processing plants operate in demanding environments with heavy loads, frequent cleaning, and exposure to harsh conditions. Mild-steel or low-quality scales wear out quickly, requiring constant repairs or replacements.

Stainless-steel floor scales, on the other hand, are:

-

Built to withstand extreme conditions such as wet floors, cold rooms, and exposure to salts or chemicals.

-

Resistant to scratches and damage, ensuring they retain accuracy even under tough use.

-

A cost-effective investment, as their long service life reduces replacement costs.

For Kenyan businesses looking for value, these scales provide excellent return on investment.

3. Precision and Accuracy in Weighing

In food processing, every gram counts. Whether it’s measuring flour for baking, portioning meat, or weighing fish for packaging, accuracy ensures consistency and minimizes waste.

Stainless-steel floor scales are engineered with high-precision load cells that guarantee accurate readings, even under frequent heavy use. Accurate weighing:

-

Improves product quality and uniformity.

-

Helps in proper stock management.

-

Prevents over-portioning, saving costs.

-

Ensures compliance with local and international weight regulations.

4. Resistance to Harsh Environments

Food processing facilities often expose equipment to moisture, steam, cleaning detergents, and temperature variations. In Kenya, where factories process everything from dairy to seafood, conditions can be especially challenging.

Stainless steel is non-reactive and remains stable even in wet, acidic, or salty environments. Unlike painted or mild-steel scales that chip or rust, stainless-steel scales retain their structural integrity, ensuring uninterrupted operations.

5. Flexibility and Wide Applications in Food Processing

Stainless-steel floor scales are versatile and can be used across many areas of food production, such as:

-

Meat and Poultry Processing – weighing carcasses, packaged cuts, and by-products.

-

Seafood Industry – weighing fish in wet, salty environments.

-

Bakeries – measuring flour, sugar, and dough batches with precision.

-

Beverage Plants – handling liquid ingredients or packaged crates.

-

Fruit and Vegetable Processing – weighing produce during sorting and packaging.

This flexibility makes them a one-stop solution for diverse needs in Kenyan food processing industries.

6. Compliance with Export Standards

Kenya is steadily growing as an exporter of food products such as processed fish, tea, coffee, vegetables, and meat. International buyers demand strict compliance with food safety and weight regulations.

By investing in stainless-steel floor scales, Kenyan food processors can:

-

Ensure accurate packaging for export.

-

Meet HACCP and ISO food safety standards.

-

Improve brand reputation and market competitiveness.

7. Cost Savings Over Time

While stainless-steel floor scales may require a slightly higher upfront investment than regular steel alternatives, they save money in the long run by:

-

Reducing downtime due to fewer repairs.

-

Lowering contamination risks that could lead to penalties.

-

Extending lifespan, meaning less frequent replacements.

For businesses in Kenya that value efficiency and cost control, this makes stainless-steel floor scales a smart financial decision.

Conclusion

The Kenyan food processing industry is rapidly evolving, with increased demand for safe, high-quality, and accurately packaged products. Stainless-steel floor scales provide the perfect balance of hygiene, durability, precision, and compliance, making them the preferred choice for businesses aiming to thrive in both local and international markets.

By choosing stainless-steel weighing solutions, you’re not only safeguarding your operations but also investing in long-term growth and customer trust.